- GH-6030AF Fully-auto Horizontal Double Side Sealer which is developed for special big items adopts advanced high speeddouble-sidesealing technology. It has up & down single film rollers. The film is in sync with the items. While the items are going forward, the side sealing system starts to seal and cut the up & down film that keeps good sealing;

- Continuous sealing& cuttingand nolimits of the item length make it particularly suitable forlonger, widerand heavyproducts’fully-closed packaging with PEfilm, such asdoors,furniture, ladders, mattressesand other heavyandoversizedobjects;

- The waste film can be winded automatically for easily clean-up;

- Sidesealing lines can beadjusted to the desired position which based onthe product’s height in order to achieveexcellentsealing strengthresults;

- For 40 ~ 120 microns thickness PE shrink film;

- Input& output conveyorsandcolored filmpositioning function can be addedas per customer demand;

- Humanizedtouchsmartoperation interface is convenient for the operator to use;

- Siemens PLC program controller achieves the integrations of mechanism, electricity and pneumatic;

- Importedphoto sensors to detect the horizontal and vertical section to satisfy different products’ packaging;

- Assortedshrink tunnelSF-15040Euses importeddoubleair circulationmotors, so that the hot air in the oven canspreadmore evenlyto get a goodshrink effect;

- PE high strength film is suitable for long distance transportation and frequent handling that can avoid damage and keep away from moisture.

- Chain bar conveying, usingsolidsteel coveredwith durable importedsilicone tube. SF-15040Ecan adddensity bar roller function which specially designed for smallproduct;

- The use of French “Schneider “inverter controls transmission speed which has the function of infinitive speed;

- The chamber lengthis short which can greatly reduce themachinepower; at same time it maintainsgoodpackingeffect;

- Applicable shrink film: PE;

- For beverage, chemical, building material, food packing with or without paper tray. And the tunnel can beused forelectrical appliances,auto parts, furniture, flooring and other individual or group sealing andshrink wrap.

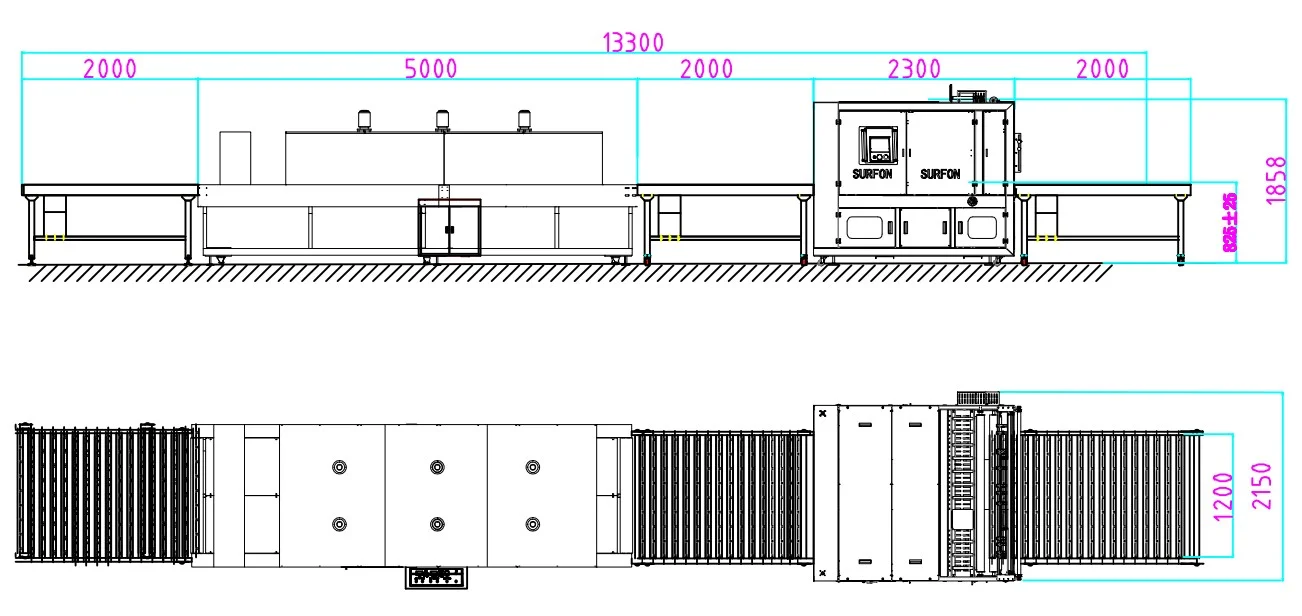

LAYOUT:

Technical Parameters

| Model | GH-6030AF | SF-15040E |

| Power | 6kw | 30kw |

| Power Supply | AC 380/220V 3PH 50/60Hz | AC 380/220V 3PH 50/60Hz |

| Max. Packing Size

L*W*H |

600mm<=W+H<=1250mm, L(unlimited ); H<=250mm |

2500×1000×250mm |

| Tunnel Size

L*W*H |

/ | 3000×1500×400mm |

| Blade Length | 1300mm | / |

| Air Temperature | 300℃ | 300℃ |

| Table Height | 825±25mm | 825±25mm |

| Packing Speed | 15m/min. | 0~18m/min. |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | PE | PE |

| Machine Size

L*W*H |

2380×1800×1780mm | 5000×1850×1850mm |

| Crate Size

L*W*H |

2430×1850×1930mm | 5050×1900×2000mm |

| G./N. Weight | 1600/1500kgs | 1950/1800kgs |