Fully-auto Column Type Sleeve Wrapper & Shrink Tunnel (Online)

GH-6030AHO+SF-6040E

GH-6030AHO + SF-6040E Automatic Sleeve Sealer and Shrink Tunnel is designed for a single item or objects without tray. This machine can connect with other production machines with the function of automatically feeding, wrapping, sealing, shrinking and cooling, unmanned assembly-line to realize unmanned operation; There are many forms of packaging : 6 bottles (2 × 3), 8 bottles (2 × 4), 9 bottle (3 × 3), 12 bottles (3 × 4), 20 bottles (4 × 5) and 24 bottles (4 × 6) etc;

Sales Manager: Mrs. Cecilia Pii

Mobile/WhatsApp/Wechat: +86 189 1774 9969

- GH-6030AHO + SF-6040E Automatic Sleeve Sealer and Shrink Tunnel is designed for a single item or objects without tray. This machine can connect with other production machines with the function of automatically feeding, wrapping, sealing, shrinking and cooling, unmanned assembly-line to realize unmanned operation; There are many forms of packaging : 6 bottles (2 × 3), 8 bottles (2 × 4), 9 bottle (3 × 3), 12 bottles (3 × 4), 20 bottles (4 × 5) and 24 bottles (4 × 6) etc;

- GH-6030AHO introduces internationally advanced technology and production process with reliable performance characteristic and also has automatic counting daily-output functions;

- The usage of Siemens PLC and touch screen to achieve the integrations of mechanism, electricity and pneumatic;

- The machine can change the packing forms according to the production requirements, such as two rows, three rows, or four rows without tray. When replacing packaging, you just convert the switch on the panel and replace the supporting material block;

- Feeding conveyor and film-feeding is smooth with gear-box motor. When packaging color film, it needs to increase the color positioning system to make accurate positioning;

- A specially designed sealing knife makes sure solid sealing line, no cracking and anti-stick;

- Feeding conveyor can be designed in the left side or right side as per your demands;

- SF-6040E using importeddoubleair circulationmotors, so that the hot air in the oven canspreadmore evenlyto get a goodshrink effect;

- Using solid steel rollers covered by silicone tubes which makes chain conveyor durable. We can also choose different material conveying chain according to the different products;

- The use of French Schneider frequency inverter controls transmission speed which has the function of infinitive speed;

- Large volume of wind cooling system makes products rapidly cooling after heat shrinking. We also can add aluminum table for your option, so that the products will not drop;

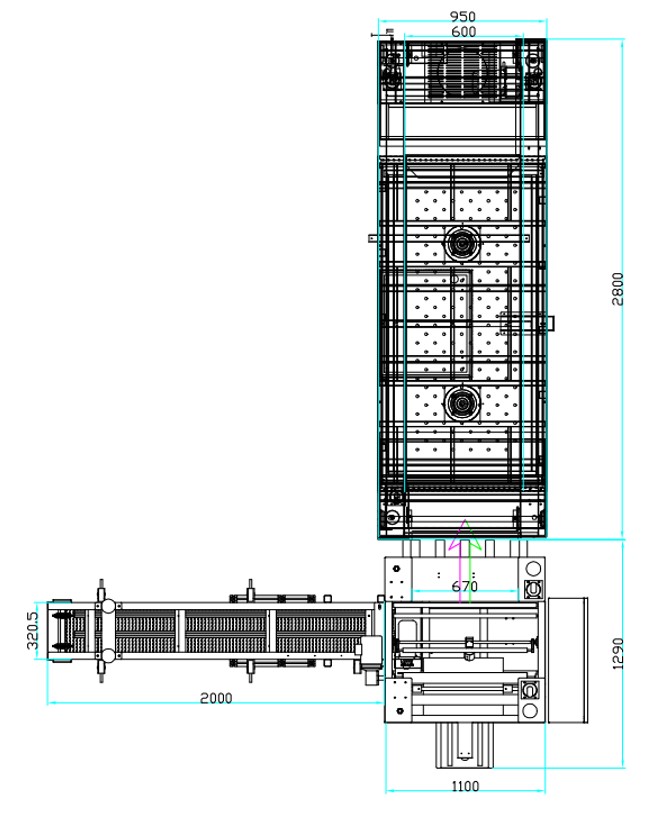

LAYOUT:

| Model | GH-6030AHO | SF-6040E |

| Power | 1.8kw | 18kw |

| Power Supply | AC220V 1/3PH 50/60Hz | AC220/380V 3PH 50/60Hz |

| Max Packing Size L×W×H | 300×500×300mm | 1500×500×300mm |

| Tunnel Size L×W×H | / | 1800×600×400mm |

| Blade Length | 670mm | / |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| Working Table Height | 820±50mm | 820±50mm |

| Packing Speed | 0-12m/min. | 0-20m/min |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | PE | PE |

| Machine Size L×W×H | 2875×1378×1813mm | 2800×950×1750mm |

| Crate Size L×W×H | 1428×900×1963mm 2100×455×760mm | 2850×1000×1900mm |

| G./N. Weight | 620/520kgs | 625/565kgs |