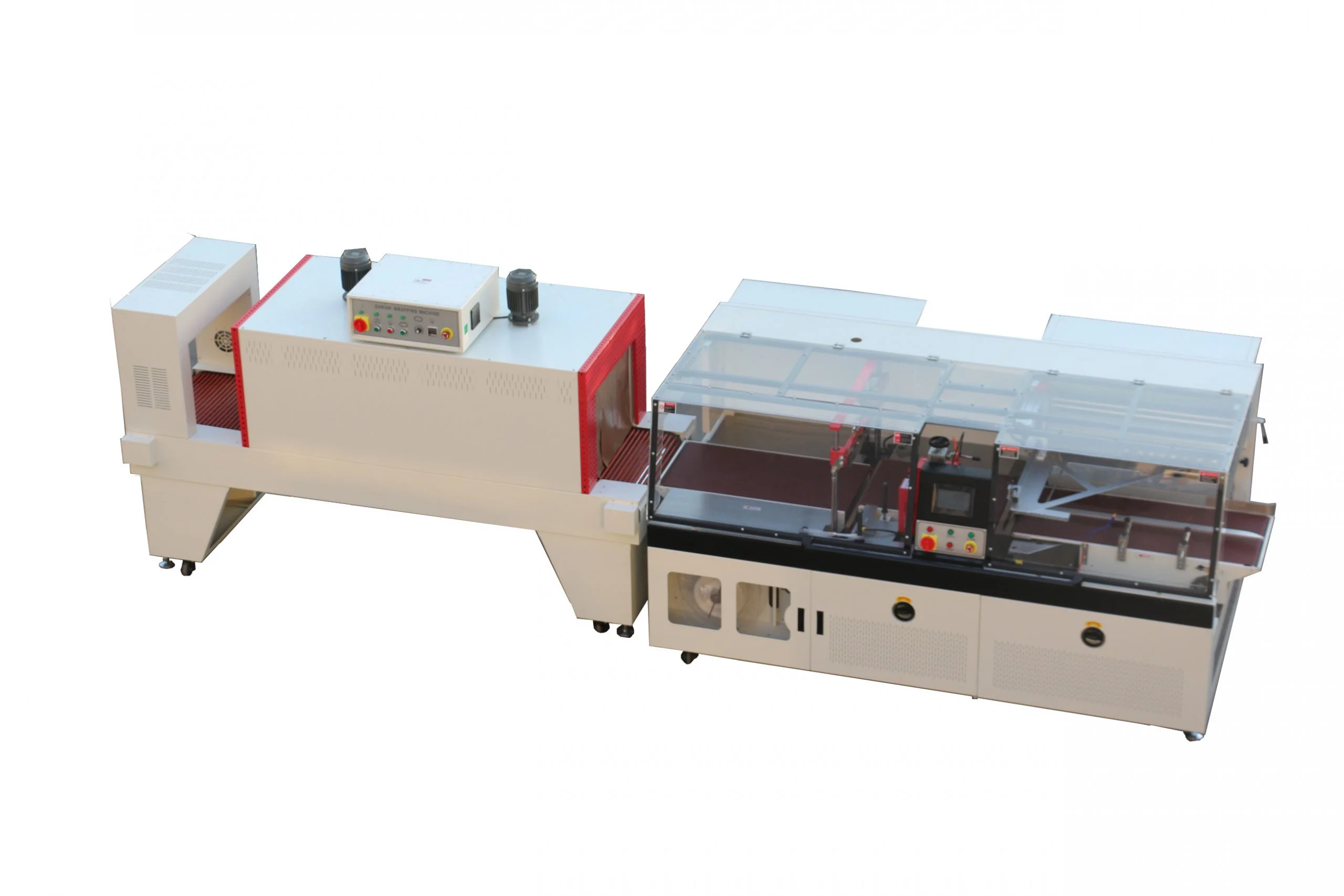

Standard Automatic Rear Type Side Sealer & Shrink Tunnel

GH-5030LH+SF-8040E

GH-5030LH Dedicated fully automatic unmanned edge banding machine is widely used in mass production lines integrating automatic feeding, conveying, sealing and shrinking. High work efficiency, suitable for products of different height and width;

Sales Manager: Mrs. Cecilia Pii

Mobile/WhatsApp/Wechat: +86 189 1774 9969

- GH-5030LH is an especial fully-auto unmanned operation side sealer by our company’s independent research and development, which is widely used in mass production assembly line with auto-feeding, conveying, sealing, shrinking in one time. It is high working efficiency and suits for the products of different height and width;

- The horizontal blade of sealing part adopts vertical driving, while the side blade uses international advanced thermostatic cutter; The sealing line is straight and strong and we can guarantee seal line in the middle of the product to achieve perfect sealing effect; This side sealing machine is different from common side sealing machine that the horizontal blade is behind of side sealing blade;

- When it packs different sizes, the adjustment is very simple by rotating the hand wheel to increase the reliability;

- Suitable for big and high products;

- The machine adopts the advanced Siemens PLC programmable controller, with safety protection and alarm devices, while the sealing system can have a continuous sealing order without replacement; Maintenance is very simple;

- Feeding length controls through a combination of electric eye detection and time relay to control precise film length that makes it easier to control the contraction effect;

- Two groups of horizontal and vertical electric eyes are easy to switch for thin or small packages which can easily complete sealing packaging operations;

- Automatic rolling waste material : Using a separate motor to control which is not too loose or too tight to crack and is easy to remove the waste;

- It has automatic blowing function;

- Front in feeding power conveyor and back non-power storage table can be selected as your demands.

- SF-8040E adopts stainless steel heating elements with automatic cooling function which greatly extended the machine’s life span more than three times. Shrinking temperature and conveyor speed can be adjusted that assures stable performance. The packaging is good sealed, anti-dust and anti-moisture;

- Generally applicable to PE shrink wrap film;

- The machine has Stable performance. Big power recycle motors ensure hot air evenly. All chain bars use solid 45 # steel and protect from external silicone tubes which can bear heavy items without film burning;

- With automatic sealer or semi-auto sealer, the operation is more convenient.

Layout:

Technical Parameter

| Model | GH-5030LH | SF-8040E |

| Power | 3kw | 28kw |

| Power Supply | AC 380V 3PH 50/60Hz | AC 380V 3PH 50/60Hz |

| Max Packing Sizes L×W×H | L(unlimited); 430<W+1.5H<900mm, H<=300mm; W<700mm |

1500x600x300mm |

| Tunnel Chamber Size L×W×H | / | 1800×800×400mm |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| Sealing Blade Length | 900mm | / |

| Working Table Height | 820±50mm | 820±50mm |

| Packing Speed | 15m/min. | 0-15m/min |

| External Air Source | 6-8kg/cm2 | / |

| Applicable Shrink Film | PE | PE |

| Machine Size L×W×H | 3435×1805×1472mm | 2800×1200×1895mm |

| Crate Size L×W×H | 3485×1855×1660mm | 2850×1250×2045mm |

| G.N. Weight | 1700/1400kgs | 900/780kgs |