- GH-6030AF Fully-auto Horizontal Double Side Sealer which is developed for special big items adopts advanced high speeddouble-sidesealing technology. It has up & down single film rollers. The film is in sync with the items. While the items are going forward, the side sealing system starts to seal and cut the up & down film that keeps good sealing;

- Continuous sealing& cuttingand nolimits of the item length make it particularly suitable forlonger, widerand heavyproducts’fully-closed packaging with PEfilm, such asdoors,furniture, ladders, mattressesand other heavyandoversizedobjects;

- The waste film can be winded automatically for easily clean-up;

- Sidesealing lines can beadjusted to the desired position which based onthe product’s height in order to achieveexcellentsealing strengthresults;

- For 40 ~ 120microns thickness PE shrink film;

- Input & output conveyors and colored film positioning function can be added as per customer demand;

- Humanized touch smart operation interface is convenient for the operator to use;

- Siemens PLC program controller achieves the integrations of mechanism, electricity and pneumatic;

- Imported photo sensors to detect the horizontal and vertical section to satisfy different products’ packaging;

- SF-20040E uses imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

- PE high strength film is suitable for long distance transportation and frequent handling that can avoid damage and keep away from moisture.

- Chain bar conveying, using solid steel covered with durable importeds ilicone tube.

- SF-20040E can add density bar roller function which specially designed for smallproduct;

- The use of French “Schneider “inverter controls transmission speed which has the function of infinitive speed;

- The tunnel adopts U type stainless steel 304 heating elements and 5-9cm thickness insulation cotton which can save thepower and prolong the machine life; meanwhile it maintainsgoodpackingeffect;

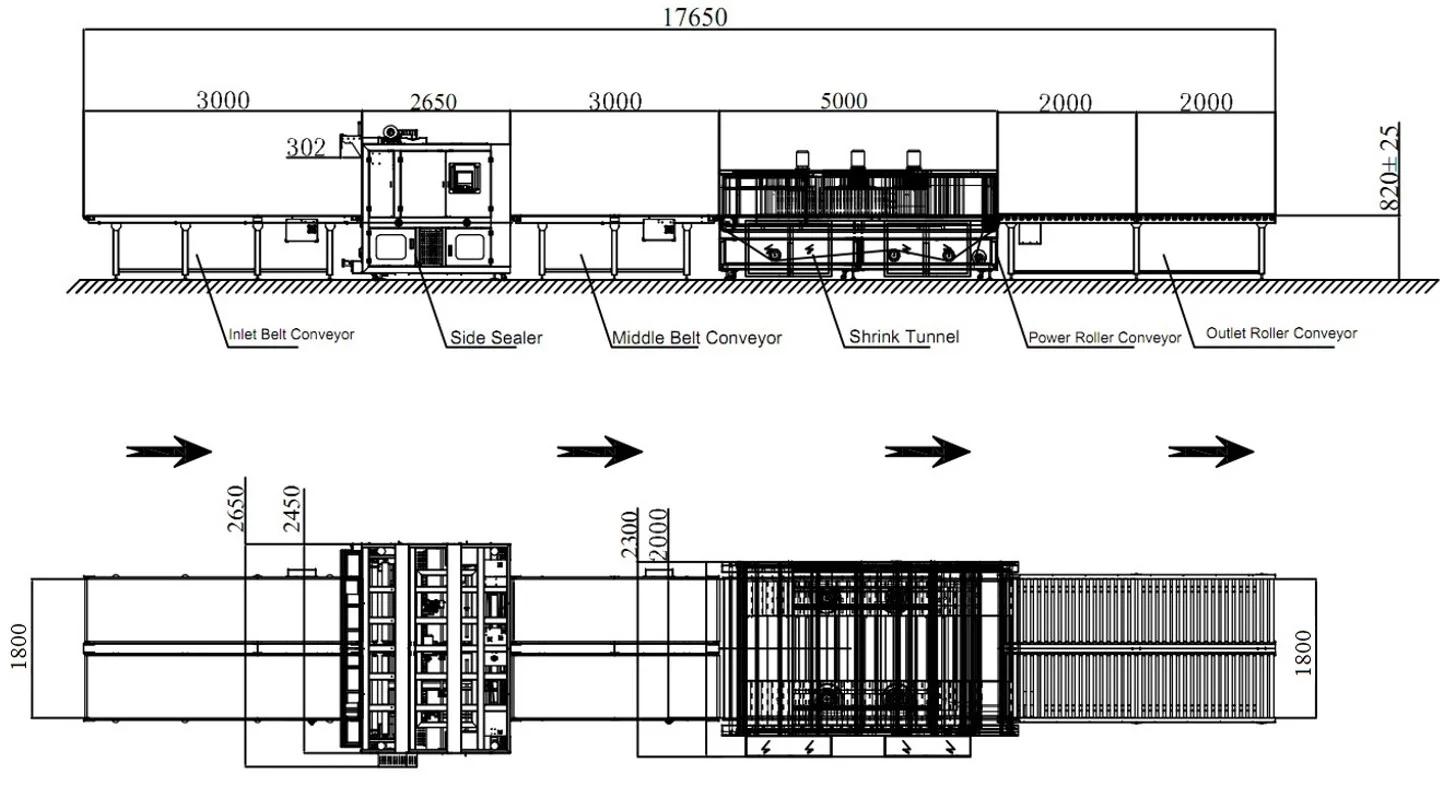

LAYOUT:

Technical Parameters:

| Model | GH-6030AF | SF-18040E |

| Power | 6kw | 45kw |

| Power supply | AC 380/220V 3PH 50/60Hz | AC 380/220V 3PH 50/60Hz |

| Max. Packing Size L×W×H | 550<W+1.5H<2000mm,

L(unlimited ); H<=250mm |

3000×1600×250mm |

| Tunnel Chamber Size L×W×H | / | 4000×1800×400mm |

| Horizontal Blade Length | 2000mm | / |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| Table Height | 825±25mm | 825±25mm |

| Packing Speed | 0-15m/min. | 0-18m/min. |

| Extra Air Source | 6-8kg/cm2 | / |

| Applicable Shrink Film | PE | PE |

| Machine Size L×W×H | 2300×2500×1900mm | 5000×2100×1850mm |

| Crate Size L×W×H | 2350×2550×2050mm | 5050×2150×2000mm |

| G./N. Weight | 2000/1900kgs | 2500/2400kgs |