PE Shrink Film

PE聚乙烯收缩膜

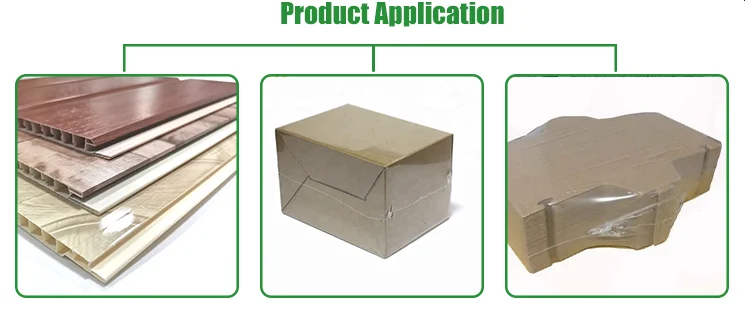

Polyethylene (PE) is a polymer obtained by polymerizing ethylene. PE is used in many forms of flexible protective packaging, including shrink wrap and stretch wrap, each with widely varying properties. PE can take many forms, but the three most common are low density polyethylene (LDPE), linear low density polyethylene (LLDPE) and high density polyethylene (HDPE). Each of these are best used in different industrial applications, but for shrink wrap, LDPE is the most common form.

Sales Manager: Mrs. Cecilia Pii

Mobile/WhatsApp/Wechat: +86 189 1774 9969

- Polyethylene (PE) is a polymer obtained by polymerizing ethylene. PE is used in many forms of flexible protective packaging, including shrink wrap and stretch wrap, each with widely varying properties.

- PE can take many forms, but the three most common are low density polyethylene (LDPE), linear low density polyethylene (LLDPE) and high density polyethylene (HDPE). Each of these are best used in different industrial applications, but for shrink wrap, LDPE is the most common form.

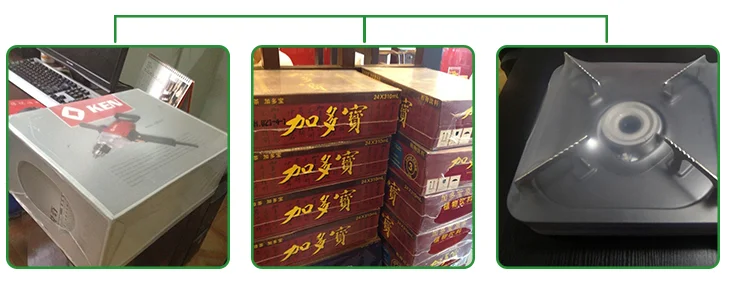

- The benefit of using LDPE over other forms of shrink wrap is the added strength and durability to heavier larger items such as beverage multipacks. These packs can also be printed and great graphics can be added while still maintaining the image and desired intensity.

- PE film thickness is usually 40, 60, 80, 100 and 120 microns. The disadvantage of PE shrinkage is that the shrinkage rate is not high, usually not more than 20%, and the transparency is much lower than other packaging papers

- Polyethylene is divided into high density polyethylene, low density polyethylene and linear low density polyethylene according to the polymerization method, molecular weight and chain structure.

- Low density polyethylene (LOW DENSITY POLYETHYLENE, LDPE) is commonly known as high pressure polyethylene. Because of its low density and the softest material, it is mainly used in plastic bags and agricultural films.

- High density polyethylene (HIGH DENSITY POLYETHYLENE, HDPE) commonly known as low pressure polyethylene, compared with LDPE and LLDPE, has higher temperature resistance, oil resistance, steam permeability resistance and resistance to environmental stress cracking, in addition to electrical insulation and resistance. It has good impact resistance and cold resistance, and is mainly used in blow molding, injection molding and other fields.

- Linear low density polyethylene (LINEAR LOW DENSITY POLYETHYLENE, LLDPE) is a copolymer of ethylene and a small amount of higher olefins polymerized in the presence of a catalyst. The appearance of LLDPE is similar to that of LDPE, but the transparency is poorer, but the surface gloss is good, and it has the advantages of low temperature toughness, high modulus, resistance to bending and stress cracking, and better impact strength at low temperature.

¨LDPE (Low Density Polyethylene) – low melting point, good tensile and strength – commonly used in food and meat products and stretch packaging/palletizing

¨LLDPE (Linear Low Density Polyethylene) – Thinner than LDPE, higher strength, better clarity – used for bulk food, frozen food, printed matter, groceries, garbage bags, palletizing/stretch packaging

¨HDPE (High Density Polyethylene) – one of the most common polymers in plastic packaging – USDA/FDA approved for food contact, lightweight, durable, water resistant, poor resistance to O2 corrosion – suitable for certain foods, retail products, Clothing, stretch wrap trays ¨

Often suitable for beverage packaging can replace corrugated paper ¨More expensive, but more durable ¨Polyethylene shrink film is recyclable ¨ thicker – provides greater stretch capacity.