Cross Linked POF Shrink Film

POF cross linked film

Multi-layer co-extrusion cross-linked shrink film is a new type of high shrinkage biaxially oriented shrink film developed on the basis of POF shrink film. Cross-linking occurs between the two membranes, so that the molecules are transformed from linear chain structures to network structures, thereby changing the physical and mechanical properties of the product. In the production of cross-linked films, different formulation designs and cross-linking degree control can be used to obtain different performance requirements. products, adapt to different packaging equipment and product packaging.

Sales Manager: Mrs. Cecilia Pii

Mobile/WhatsApp/Wechat: +86 189 1774 9969

多层共挤交联收缩膜是在POF收缩膜的基础上开发的一种新型高收缩率双向拉伸收缩膜.它是将多层共挤PE收缩膜通过高压电子束辐射使PE的分子之间发生交联,使分子由线形链状结构转化为网状结构,从而使产品的物理机械性能发生改变.交联膜生产中通过不同的配方设计和交联度控制可以制得不同性能要求的产品,适应于不同的包装设备和产品包装.

用于软包装材料的最常见的交联形式是辐照交联。辐照交联使用产生高能B射线的电子束。在辐照过程中,薄膜内的不同键交联在一起。

- 增强的抗穿刺性- 聚合物的交联提高了抗穿刺性,使用户可以使用更薄的薄膜,同时仍获得相同的强度。较薄的薄膜具有多种优势,其主要优势是成本。较薄的收缩膜还可以提供更好的透明度,更快的密封性和更快的收缩率。

- 更高的密封强度-收缩包装的最薄弱之处是密封缝。标准收缩膜不能获得与交联收缩膜相同的密封强度。更强的密封性可以减少损坏的包装,并确保客户购买未经篡改的产品。

- 残留物少-随着时间的流逝,收缩膜将残留物留在密封线或刮刀上。残留的残留物导致需要更换密封线和刀片。对于每天制造数千个密封件的全自动机器,减少残留物是节省时间和减少更换密封片数量的理想选择。

- 更高的清晰度-使用具有同等强度的较薄薄膜的能力可提高收缩薄膜的清晰度。辐照交联的收缩膜还具有较少的雾度,以提高清晰度。

- 交联膜收缩率比POF膜更高(双向均在70%以上,POF膜为60%),收缩温度降低

- 比POF膜热封强度高,热温度范围宽。

- 交联膜包装后膜表面摩擦不存在POF膜易出现此案的脱层问题。

- 交联膜时效处理和储存过程中自然收缩率降低质量比POF膜低。

- 交联膜的厚薄均匀度优于非交联膜。

- 交联膜挺度和表面硬度增加,耐表面机械划伤。

- 利用特殊配方和工艺控制参数可以制得高收缩率,低收缩力的交联收缩膜,而POF膜不可以。

- 由于交联膜起始收缩温度降低,在商品包装过程中一定程度上增加了收缩时间,使收缩过程缓和,降低了被包装物质变形和损伤的机会。

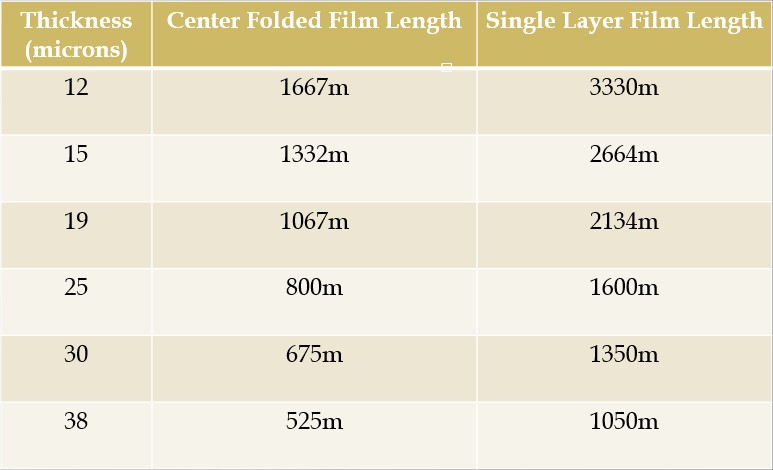

Technical Parameters:

- High Speed Shrink Wrapper – Fully automatic and semi-automatic shrink wrapping machines that pack thousands of products per day are ideal for cross-linking shrink films. For fully automatic machines, cross-linked polyolefin shrink film will greatly reduce the difficulty

- Lightweight Products – For lightweight products weighing up to a few ounces, a cross-linked shrink film can be used. The lighter 12-micron cross-linked shrink film can provide lower professional packaging costs than standard 15-micron polyolefin shrink films.

- Heavy Product – 25 micron cross-linked shrink film is stronger and provides higher seal strength than standard 25 micron shrink film. Standard 25 micron shrink film is usually not enough to withstand heavier products. Instead of polyethylene shrink film, try a cross-linked 25-micron polyolefin film.

- Products with Sharp Edges – Due to the increased strength of the cross-linked shrink film, it is often a better choice for products with sharp edges and corners. Cross-linked films can help ensure products reach customers without tampering.