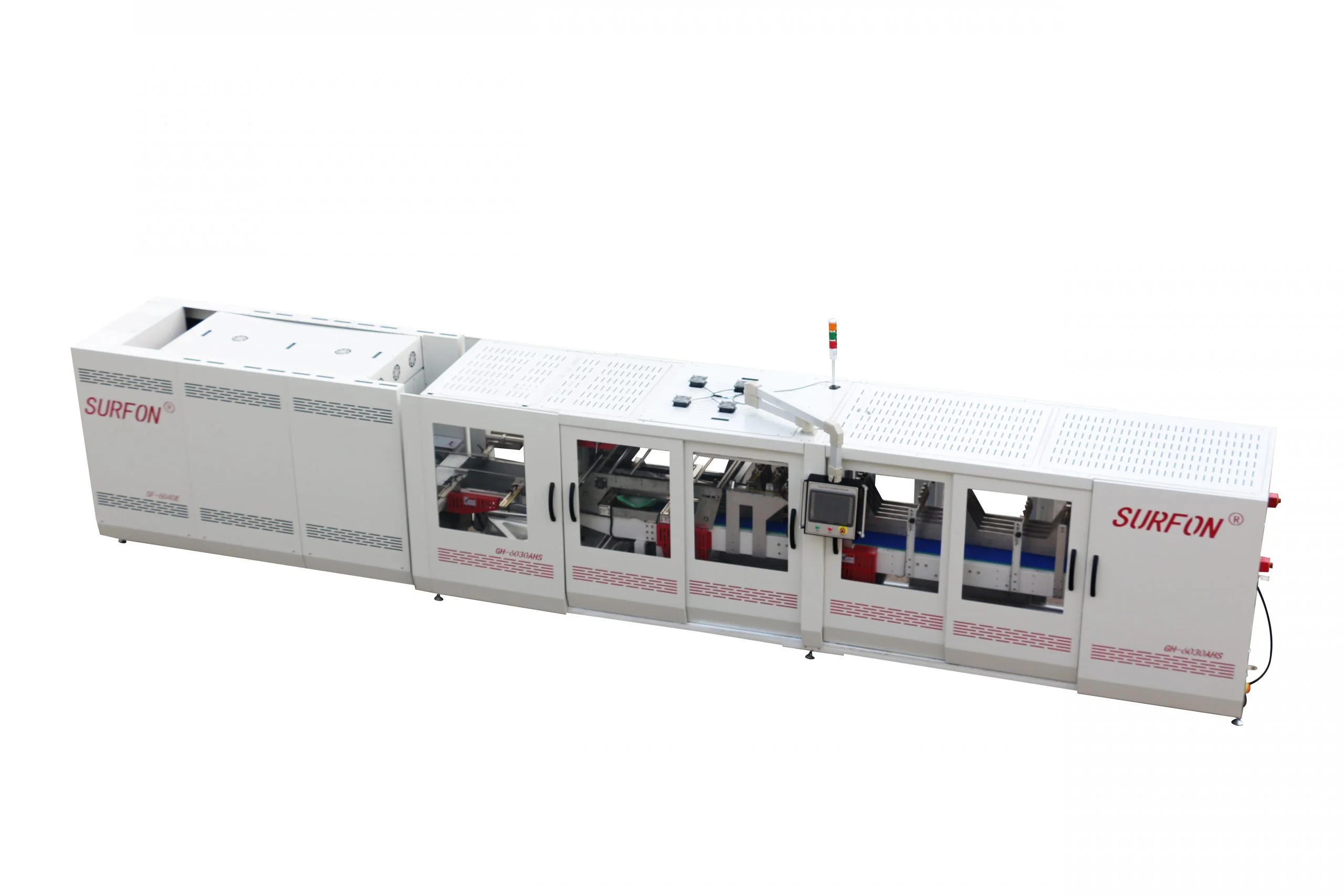

Automatic High Speed Bottle Sleeve Wrapper & Shrink Tunnel

GH-6030AHS+SF-6040E

GH-6030AHS+SF-6040E is a fully automatic unmanned sealing, cutting and shrinking packaging machine independently developed by our company. It is widely used in the assembly line of mass production packaging, with high work efficiency;

Sales Manager: Mrs. Cecilia Pii

Mobile/WhatsApp/Wechat: +86 189 1774 9969

- GH-6030AHS+SF-6040E is a fully automatic unmanned sealing, cutting and shrinking packaging machine independently developed by our company. It is widely used in the assembly line of mass production packaging, with high work efficiency;

- GH-6030AHS is a linear packaging machine that can be customized for the production of bee flower conditioner similar to bottle-shaped products.

- The closed design improves the safety of the equipment; the visual window design makes the product packaging process clearly visible; the external touch screen display and operation greatly increases the convenience of operation;

- The original imported motor is used to make the conveying, pushing and sealing and cutting more stable, and the core part is driven by a servo motor to achieve higher efficiency packaging; Using a specially designed sealing knife, the sealing line is firm, not cracked and not easy to stick to the knife;

- SF-6040E adopts dual-transport fan motors, the hot air volume in the furnace cavity is uniform, and the effect is beautiful after shrinkage;

- The solid steel rod is used to cover the imported silicone tube, and the chain-rod conveying is durable. Conveyor chains of different materials can also be used according to different products;

- The discharge port is equipped with a cooling fan, so that the product can be quickly cooled and shaped after heat shrinkage.

- This machine is equipped with Schneider PLC programmable controller and intelligent touch screen, which realizes the integration of machine, electricity and gas, and has safety protection and alarm devices.

- The use of imported electrical components reduces failures during use;

- It is suitable for sealing, cutting and shrinking packaging of beer, mineral water, cans, glass bottles, plastic bottles and other round products without support.

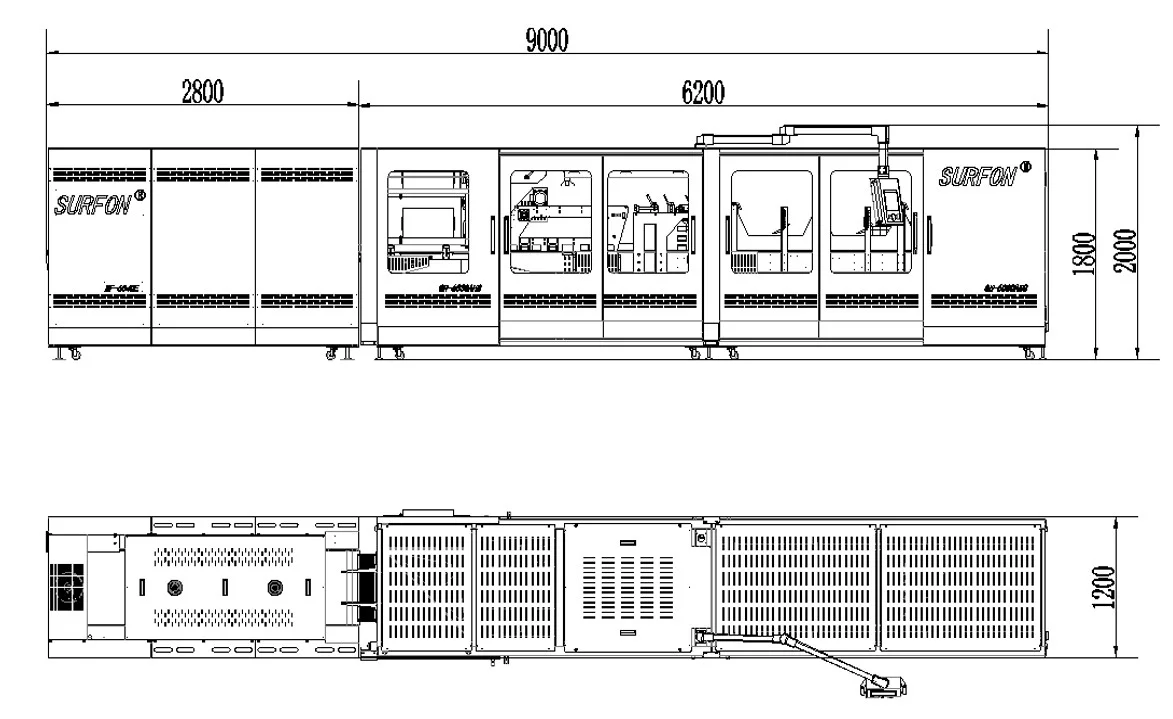

LAYOUT:

Technical Parameters:

| Model | GH-6030AHS | SF-6040E |

| Power | 1.8kw | 28kw |

| Power Supply | AC220V 1/3PH 50/60Hz | AC220/380V 3PH 50/60Hz |

| Max Packing Size L×W×H | 300×500×300mm | 1500×500×300mm |

| Tunnel Chamber Size L×W×H | / | 1800×600×400mm |

| Blade Length | 670mm | / |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| Working Table Height | 820±50mm | 820±50mm |

| Packing Speed | 0-12m/min. | 0-20m/min |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | PE | PE |

| Machine Size L×W×H | 6200×1200×2000mm | 2800×950×1750mm |

| Crate Size L×W×H | 6250×1250×2150mm | 2850×1000×1900mm |

| G./N. Weight | 2450/2050kgs | 625/565kgs |